Electrical Service and Emergency Repair

Blakeslee Electric’s service department is on call 24 hours a day to meet our customer’s needs. Our service fleet of trucks is well equipped so we can dispatch quickly and are ready to work when we arrive on site. What’s more, we have 3000 square feet of warehouse space dedicated to service inventory so that we will have what you need, when you need it. You will find our service technicians friendly, knowledgeable and efficient. Lastly, we do not charge for services based on a flat rate, you only pay for the labor and materials actually required to complete your project.

We also offer a variety of services less common to our industry and we are certified in each of these disciplines. You may follow the links below to read more about each specialty. Please don’t hesitate to contact us for more info.

Preventative Maintenance

We understand that the reliability of your electrical system is critical to the operation of your business. That’s why we invest in the most advanced tools available to predict an electrical system failure before it happens. Using both infrared and ultrasonic scanning we are able to locate most small problems before they become big ones. Our preventative maintenance services provide you with initial test reports as well as a system to track and verify your repairs. Blakeslee Electric has been providing these services for almost two decades and is the recognized leader in preventative inspections services in the North Bay area.

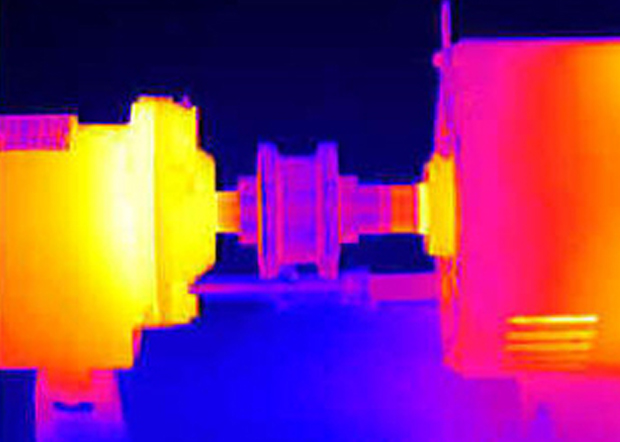

Infrared Inspection

Exactly what is it?

Infrared imaging equipment allows us to see the invisible part of the spectrum contiguous to the red end of visible light. That is, we can see heat. The energy that is emitted from warm objects is translated into visible light and presented in multiple colors so that we can “see” the temperature. Images of problem spots are captured and stored on a computer memory card for further analysis using specialized software. Hidden electrical and mechanical problems can be easily located and corrected before an actual failure occurs.

Why use infrared imaging?

With any electrical distribution equipment heat is the enemy. Infrared scanning is your early warning system for excess heat. By finding problems early you can protect them before additional damage or system failure occurs. Most often problems that are detected early require only minor repairs.

How often should it be done?

Infrared imaging is the core of a good electrical preventative maintenance program. Most companies that utilize infrared for preventative maintenance perform this operation once annually.

Will I have to shut down the power?

No. Infrared imaging is done during the normal operation of the electrical system.

Can it cause damage to my electrical system?

No. Infrared imaging is completely non-destructive. There is no contact with the current carrying electrical components.

Ultrasonic Electrical Inspection

Why use Ultrasonic Inspection?

Ultrasound inspection may be performed at all voltages (low, medium and high). When electrical equipment such as switchgear, transformers, insulators or disconnects and splices fail, the results can be catastrophic. This is just as true in industrial plants as it is in the power transmission and distribution side. Electrical discharges such as arcing, tracking or, in higher voltages, corona have the potential to create equipment failure and costly downtime. In addition, the problems of RFI and TVI impact on our valuable communication networks. If left undetected, these conditions can become a source of an arc flash incident, which can result in severe injury or death. Arcing, tracking and corona produce ultrasound and are detected with an Ultraprobe.

How Does Ultrasonic Electrical Detection Work?

Arcing, tracking and corona all produce ionization which disturbs the surrounding air molecules. An Ultraprobe detects high frequency sounds produced by these emissions and translates them (via heterodyning) down into the audible ranges. The specific sound quality of each type of emission is heard in headphones while the intensity of the signal is observed on a display panel. These sounds may be recorded and analyzed through ultrasound spectral analysis software for a more accurate diagnosis. Normally, electrical equipment should be silent, although some equipment such as transformers may produce a constant 60 cycle hum or some steady mechanical noises. These should not be confused with the erratic, sizzling frying, uneven and popping sound of an electrical discharge.

Construction

Blakeslee Electric, Inc. provides a complete construction solution for all of your electrical needs. We are your one-stop provider for line voltage electrical systems, telecommunications systems, access control and CCTV camera systems. We can provide these services using a variety of delivery vehicles, including:

- Design Build with preconstruction services

- Lump Sum Contract based on your plans and specifications

- Time and Material and “Not To Exceed” contracts

- Lean Construction Delivery

Power Quality

We have the latest power quality and power demand metering equipment so that we can provide effective solutions for any power problem you may have, and we have the expertise to back it up. We offer three, five and thirty-day power demand surveys to meet the California OSHPD design criteria, as well as customized power quality surveys. This is just part of our commitment to providing our customers with the most comprehensive electrical service available.

Green Technology

More Information Coming Soon!